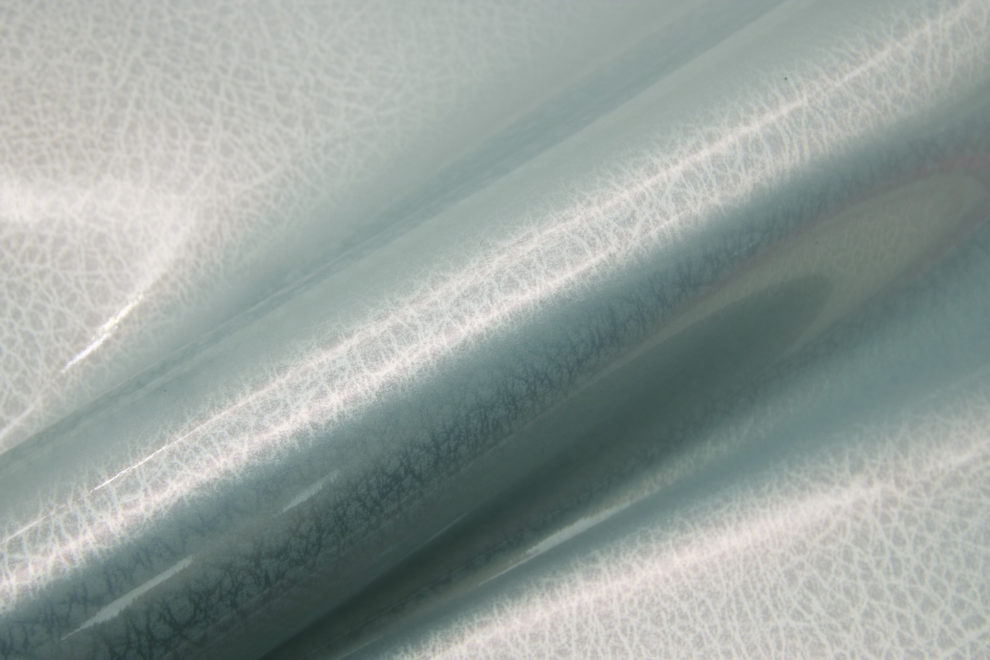

Firebird

Specialized color-shifting surface effect, graphic base with a tumbled grain, and clear patent finish on top, producing textural depth with an overall “under glass” effect.

SKU: A629

PANTONE Colors

We are able to match any Pantone color at your request

- Colors shown here are season trends

-

We are able to match any Pantone color at your request

3D Image Maps

Please send us a message here

or find us on Swatchbook

- ALPHA·BASE·DISP·MTL·RNM·ROUGH

-

Please send us a message here

or find us on Swatchbook

Price validity:

01 JUL 2023 to 31 DEC 2023

Based on USD 1 = NTD 29

Split Leather surcharge

1.2mm – 1.4mm: no surcharge

Unlined = $0.03/SF

1.6mm – 1.8mm = $0.10/SF

1.8mm – 2.0mm = $0.15/SF

WP = $0.30/SF

Synthetics surcharge

WP = $3.50/LY 52” ($0.27/SF)

MOQ:

Split Leather: 1000 SF

Others: 100 LY 52”

Surface Bonding:

Some articles may require surface buffing to achieve minimum performance standards for bonding to midsole IF used in midsole bonding margin AND regardless of substrate chosen.

Vulc & Temp Limitations:

Heat Condition Temp & Time: 120C is the maximum temp.

120C @ 90min is the upper range of suitable conditions.

Discoloration / Hand Feeling: The surface color of some nubuck articles may become darker with high heat processes

Color Migration:

The unique Process used to make these complex type surface finishes may yield higher color migration compared to simple type PU coated finishes.

HM Film Condition:

The temp of the HM film layer has to reach 110C detected by the thermal detector. Some articles may be induced gloss or color changed by the higher temp process.