We are aiming to become DMF-free by 2025

DMF (Dimethyl Formamide) has strong solubility to many organic substances and is completely miscible with water. It is often used as a solvent for polymer materials and resin. In the PU Leather industry, this has long been a widely used organic solvent. At PONY, we have never neglected the impact of the organic solvent on the environment and even on the health of end consumers.

Since 1984, PONY has set up a distillation tower for DMF recovery. DMF has excellent solubility in water, but after a period of operation in a wet scrubber, the efficiency of liquid absorption will be due to the fact that a certain amount of DMF has been dissolved in the stripping liquid. Gradually decreases. At the same time, the DMF washed at a high concentration is easily stripped off by the stripping of the low-concentration exhaust gas. Our engineers designed a process that uses a gas-liquid counter-current, three-stage (3 series) packed packing tower to ensure DMF emissions are minimized.

Tremendous progress has been made in the last 10 years

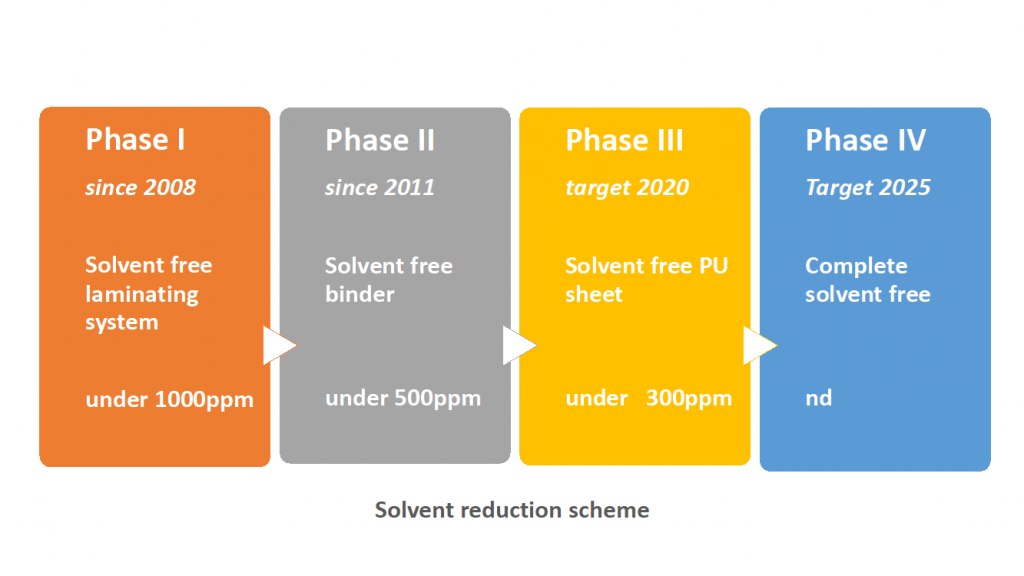

In addition to recycling and reducing emissions, PONY understands that reducing the use of DMF from the process is the fundamental solution. Our R&D staff has been focusing on reducing the use of DMF in the process. The DMF content of PONY’s products has dropped from over 2,000 ppm before 2008 to below 500 ppm. Our R&D team is working towards the goal of zero organic solvent processes.